Anti-Foam Control Solutions-- High-Performance Anti-Foam Products for Several Industries

Anti-Foam Control Solutions-- High-Performance Anti-Foam Products for Several Industries

Blog Article

Best Practices for Choosing the Right Anti-Foam Control Option for Your Needs

Choosing an efficient anti-foam control option requires a detailed examination of your one-of-a-kind functional demands. Secret considerations include the specific residential or commercial properties of your procedure, such as ph, chemical, and temperature communications, all of which dramatically influence the performance of defoaming representatives.

Understand Your Foam Issue

Frequently, companies run into foam-related concerns that can hinder operational effectiveness and item top quality. Foam development can happen during numerous procedures, including mixing, fermenting, and transportation, and it usually results in tools inadequacies, manufacturing downtime, and enhanced operational expenses. Comprehending the underlying sources of foam generation is essential for dealing with the problem properly.

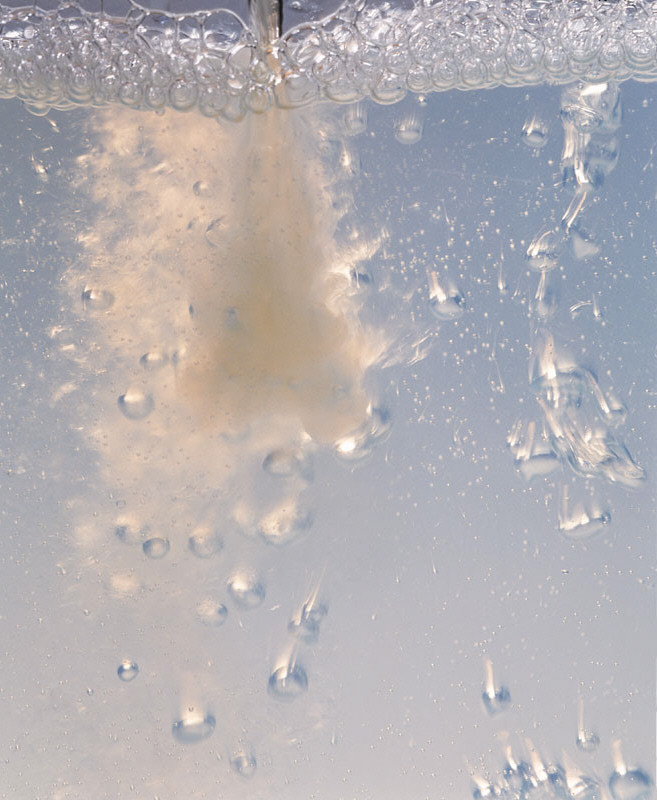

Foam can emerge from numerous elements, such as the nature of the materials entailed, agitation degrees, temperature variants, and chemical responses. For instance, certain surfactants can aggravate lathering, while high shear blending can present air, resulting in unwanted foam build-up. Additionally, ecological problems and the certain characteristics of the fluid systems in use can considerably affect foam behavior.

Determining the kind of foam-- whether it is unstable or steady-- is also crucial. Stable foam often tends to persist longer and is much more tough to manage, while unpredictable foam may dissipate more easily. Anti-Foam Control Solutions. By analyzing these variables, organizations can acquire understandings right into their foam issues, enabling them to establish targeted techniques to minimize foam formation and boost total process performance. This foundational understanding is crucial for picking an appropriate anti-foam control option customized to certain functional needs.

Review Anti-Foam Options

When considering anti-foam options, it is important to thoroughly assess the various formulations available on the marketplace to locate one of the most ideal solution for your specific foam-related obstacles. Anti-foam representatives been available in diverse types, including silicone-based, non-silicone, and all-natural solutions, each offering unique residential properties and performance attributes.

Begin by evaluating the particular application requirements, such as temperature level limits, pH levels, and the kind of foam being created. As an example, silicone-based representatives are recognized for their performance in high-temperature atmospheres, while non-silicone options may be preferable in food handling applications because of governing factors to consider.

It is likewise essential to think about the rate of application and the wanted durability of the foam control. Some formulations may give instant defoaming action, while others use prolonged stability. Conducting small tests can offer understandings right into the effectiveness of each choice in real-world conditions.

Take Into Consideration Application Compatibility

In the world of anti-foam solutions, ensuring application compatibility is paramount for attaining optimum efficiency. The effectiveness of an anti-foam representative largely depends upon its capacity to work harmoniously within the particular parameters of your application, consisting of temperature, pH, and the presence of various other chemicals. Different formulations might execute variably throughout diverse problems, therefore extensive screening is crucial.

Begin by recognizing the attributes of your process, such as thickness and the nature of the tool in which the anti-foam will be used. For circumstances, some anti-foam representatives may function well in aqueous solutions yet stop working in natural solvents. Additionally, take into consideration the prospective communications with existing materials and ingredients to stay clear of unfavorable effects.

It is likewise important to examine the method of application. Whether the anti-foam is presented continuously or batch-wise can influence its efficiency and durability in the system. Ensure that the selected item is not only suitable with the operational parameters but likewise straightens with any type of governing requirements significant to your industry.

Assess Environmental Effect

How does the environmental influence of an anti-foam control solution influence your total selection process? The eco-friendly impact of your chosen anti-foam agent is extremely important, as it shows your dedication to sustainability and regulative conformity. Selecting a product with very little ecological repercussions can enhance your business picture and foster consumer trust.

When examining ecological influence, think about the biodegradability of the anti-foam option. Biodegradable choices are normally better, as they break down more quickly and minimize long-lasting eco-friendly injury. In addition, examine the possibility for bioaccumulation and toxicity to aquatic life. Solutions with high toxicity can pose significant risks to local environments, possibly causing governing fines and environmental degradation.

An additional critical factor is the presence of unsafe materials. Anti-foams having unsafe chemicals might require special handling and disposal measures, making complex and boosting functional costs compliance with ecological policies. For that reason, selecting great site eco-friendly choices can reduce these risks.

Display and Enhance Performance

To make the most of the performance of your anti-foam control service, it is vital to frequently monitor and optimize its efficiency. Continual examination enables for the recognition of any variances in foam degrees and the succeeding performance of the anti-foam agent.

Apply a methodical strategy to keep track of key performance signs (KPIs), such as foam quantity, stability, and the action time of the anti-foam agent. Use logical tools and methods, such as aesthetic evaluations, foam elevation measurements, and specialized sensing units, to collect accurate information.

Additionally, preserve open address communication with vendors for technical assistance and understandings on the newest advancements in anti-foam innovation. This proactive technique not only help in achieving ideal performance however also reduces functional disruptions and improves total process performance. Routinely taking another look at and refining your anti-foam method ensures that you are successfully taking care of foam-related challenges, eventually bring about improved efficiency and price financial savings.

Final Thought

In conclusion, choosing the ideal anti-foam control solution requires a thorough assessment of certain application demands, including temperature, pH levels, and chemical compatibility. Sticking to these ideal techniques will certainly help with educated decision-making in anti-foam control options.

Picking an effective anti-foam control service requires a thorough evaluation of your distinct operational demands.In the world of anti-foam solutions, guaranteeing application compatibility is vital for attaining optimal performance.Exactly how does the environmental effect of an anti-foam control option affect your general choice process?In final thought, choosing the proper anti-foam view it control option demands a thorough analysis of details application demands, including temperature, pH degrees, and chemical compatibility (Anti-Foam Control Solutions). Adhering to these best practices will facilitate informed decision-making in anti-foam control solutions

Report this page